Introducing STG Combustion Control GmbH & Co KG

Advanced Combustion Control for Glass Melting Furnaces

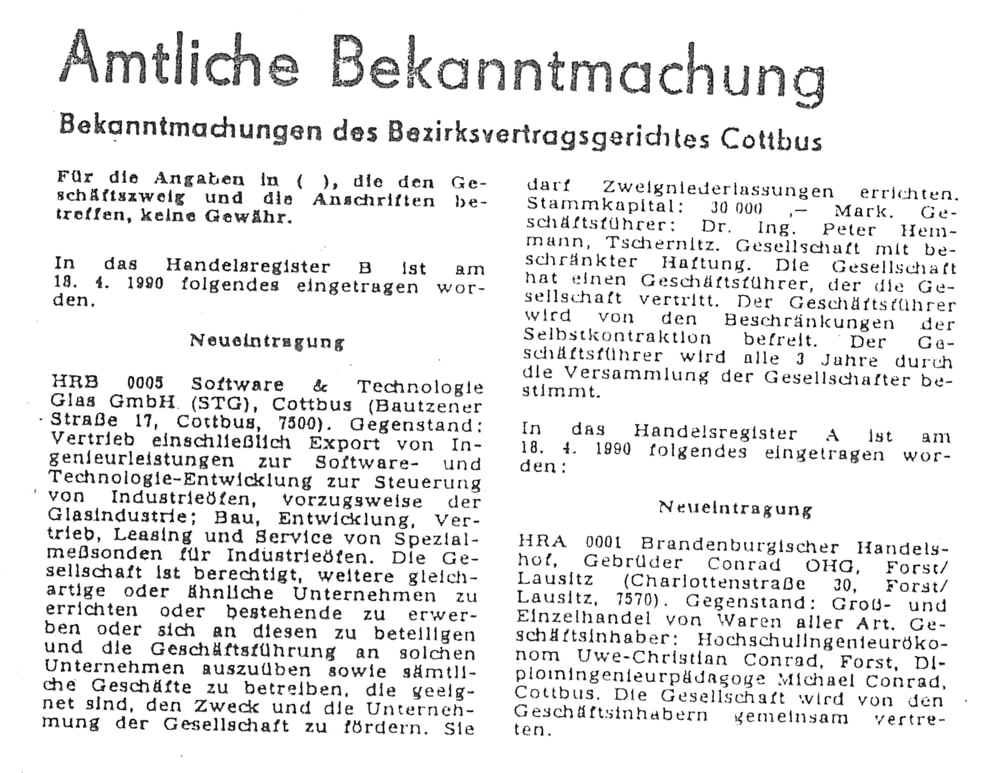

STG was founded on 18 April 1990 by three process engineers and friends from university as "Software & Technologie Glas GmbH".

Having grown steadily over the years through numerous projects and operating since 2012 as "STG Combustion Control GmbH & Co KG", our team of more than 60 highly qualified engineers, software developers and technicians develops pioneering solutions for the requirements of a modern and sustainable industrial production.

As a renowned partner to the international Glass Industry, our satisfied customers now also include the Steel, Chemical and Biotechnology sectors.

From the very beginning, we have focused on the ever-increasing demands for energy efficiency, emission reduction and process control.

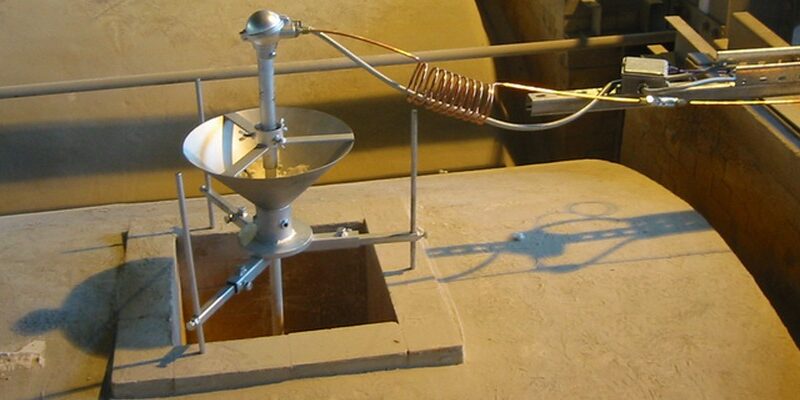

The combination of state-of-the-art measurement and control technologies and the continuous development of advanced optimisation concepts make STG the ideal partner for almost all Hot End control tasks - from oxygen measurement with zirconium oxide probes to complex process control systems.

And we know that: No two projects are the same, especially today. That's why, of course, no control system comes "off the shelf", but is always tailored to the specific needs of the customer.

Powerful, efficient, sustainable. And always customised.

Optimise your combustion process by combining STG technologies

Process Control System

- Hot End Furnace Control Systems for:

- Batch House

- Furnace

- Tin Bath / Lehr

- Forehearth / Feeder

- Fiberizing

- Hard- & Software Engineering

- Control cabinets assembling

- Frequency Drives and Field Devices

- Network (Fibre Optics / Ethernet...)

- Commissioning on site

Oxygen measurement / Advanced Signal Processing & Lambda Control

- High temperature in-situ Oxygen sensors

- Advanced Signal Processing: Monitoring O2 / CO / Lambda / Air ingress

- Lambda Control (integrated in Furnace Control System)

- Installation and commissioning

- Renting & Service contracts

Calorimeter & Energy based Lambda Control

- Precision Calorimeter for monitoring of gas quality changes

- Patented Sofware functionality "STG Energy Based Lambda Control" for automatic compensation of gas quality variations (integrated in Furnace Control System)

- Commissioning on site

Further performances

- Furnace Pressure sensors

- Energy Management Systems (EMS)

- Combustion air flow Control

- Air Curtain System for optimized distribution of combustion air

- Optical Melting Control (OMC)

- FlammaTec burners (Gas/Oil/Dual, Oxy Gas, Hydrogen)

Detailed product information following soon...

Management

Starting from the left:

- Norwid Hemmann, Senior Programmer (Shareholder)

- Matthias Schuetzel, Project Manager Automation / Process Technology (Shareholder)

- Werner Bengsch, Managing Director Production / Logistics Logistik

- Dr. Peter Hemmann, Co-Founder / Senior Specialist Combustion Control processes

- Helmut Heelemann, Co-Founder / Senior Specialist Sensor Technologies

- Andreas Birle, Managing Director Combustion Engineeringk

- Thomas Schulz, Managing Director Process Automation