Industrial Automation and Process Control Systems

Europe's No. 1 for the process automation of float glass plants

In a few words :

No other European company has more experience in float line process automation than STG Combustion Control.

Since 1990, STG has carried out more than 150 major automation projects for customers in the glass industry.

Our references include around 80 float glass lines and over 50 container glass furnaces.

Unlike many of our competitors, we do not offer "off-the-shelf" systems, but always tailor made solutions for our customers.

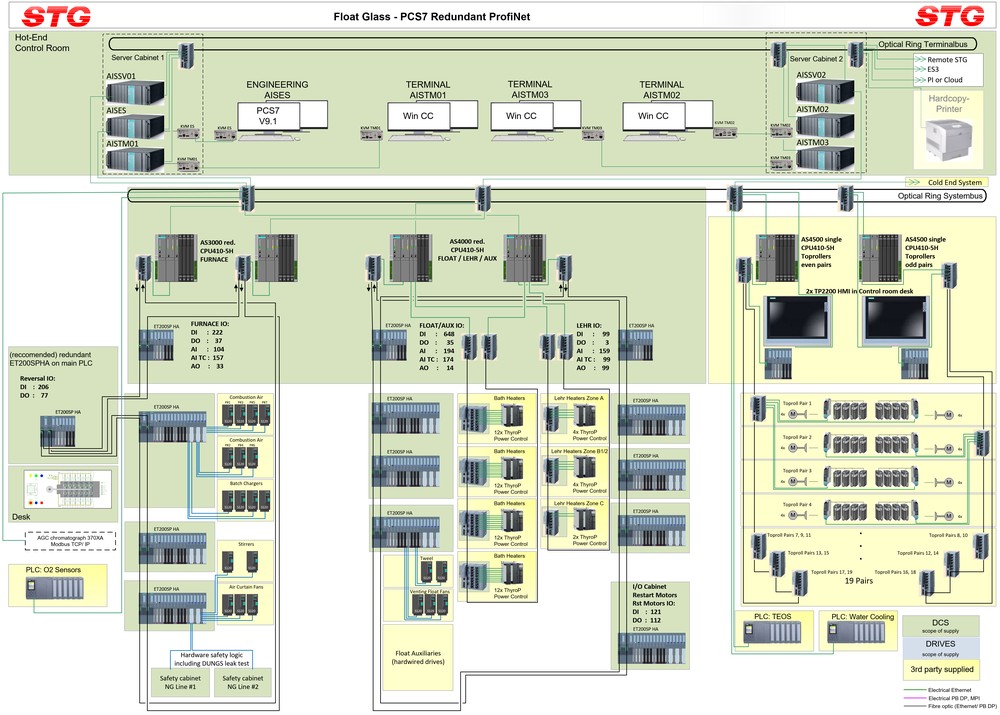

Planning of optimal control system design

Engineering

- Hardware ( Cabinets planning, Field planning, disposition of components)

- Software (DCS, CPU, Visualization)

Control cabinets assembly

- Control cabinets CPU / Network / Fibre optics

- Control cabinets frequency converters

- Uninterrupted Power Supply (UPS)

Signal Test and FAT

Installation and Commissioning

Process optimisation

Documentation and Training

Disposition, delivery and installation of field devices (Pressure, Temperature, Flow rate…)

Disposition, delivery and installation of Frequency converters

Delivery and installation of cable trays

Control room furniture (e.g. Desks, Video walls, Networks, Server cabinets)

Bus systems (DP, PA, redundant, fibre-optic, copper)

Disposition, delivery and termination of fibre optics systems

SIEMENS PCS7

SIMATIC S7/S5

Allen-Bradley (Rockwell)

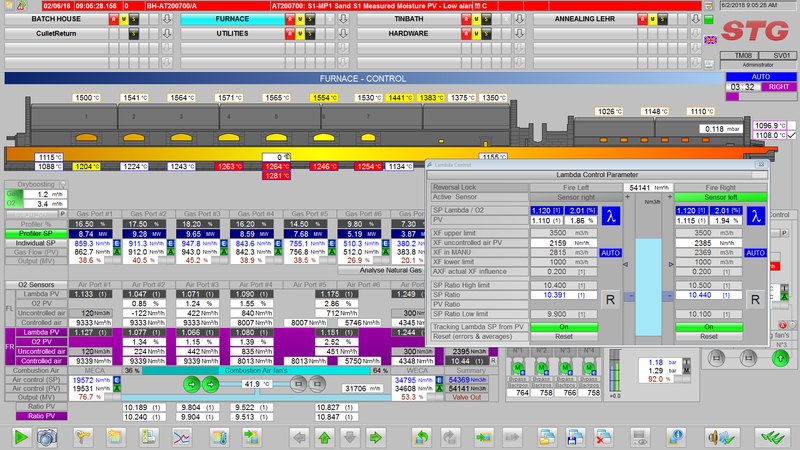

WinCC / WinTM

Energy Management System (EMS)

Intellution iFIX

ePLAN

BTR Furnace Temperature Control

Flexible Energy Control

Energy Based Lambda Control

Solutions for redundant system design

Long term data bases

Energy Management System (EMS)

Special program module for fine tuning of reversal sequence

Further specialized and industry proven control loops

Extras:

PLC integrated model based function blocks for energy optimisation and a proactive operational mode

PLC integrated Lambda Control based on Oxygen Sensors, also for Dual (Gas /Oil) and OxyFuel firing

PLC integrated combustion calculation

BTR Furnace Temperature Control

Automatical symmetry control of furnace heating

Recipe management for feeder and top roll machines

Best available system safety due to

- Offline tests in Cottbus with STG and customer staff

- Optimized and custom-fit system architectures, e.g.:

- Redundant PLC

- Single PLC with bumpless Backup

- Distributed redundancy

STG is certified as "Siemens Solution Partner - Automation Drives"

Portfolio Module “Process Control System PCS 7”

Expert Module "PCS7 Applications"

Expert Module “Glass”

STG is certified for Quality Management System acc. to ISO 9001:2015

for the scope of certification: "System integrator for the glass industry / chemical industry / steel industry / biotechnology"

STG is certified for Environmental Management System acc. to ISO 14001:2015

for the scope of certification: "System integrator for the glass industry / chemical industry / steel industry / biotechnology"

Get in touch with

Dr. Peter Hemmann